AUTRES GROUPES DE PRODUITS

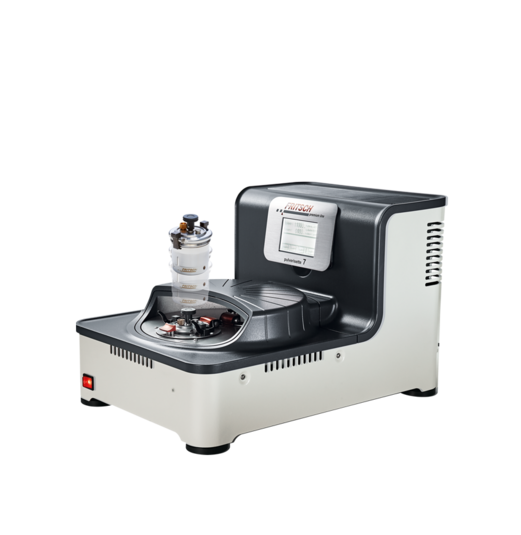

Mixeur homogénéisateur à couteaux

PULVERISETTE 11

Pour une adaptation spécifique à votre application, nous offrons des accessoires complémentaires. Un récipient de broyage de 1,4 l en plastique transparent anti-rayures, autoclavable avec un couvercle standard et le couteau standard en acier inoxydable 316L qui sont inclus dans le prix de base de l'instrument. Lors de la commande d'une configuration différente des accessoires standards, veuillez préciser le numéro d'article exact de la pièce à remplacer.

Les durées de broyage de la PULVERISETTE 11 sont tellement courtes qu’il est possible de traiter des échantillons très rapidement. Il est donc rentable de commander plusieurs cuves de broyage pour les utiliser en parallèle.

Autres couteaux sur demande !

Toutes les pièces en contact avec l'échantillon sont autoclavables.

Cuves de broyage de 1,4 litre

-

Cuves de broyage de 1,4 litres

Pour tous les échantillons standards Pour une observation optimale du processus de broyage

Cuve de broyage standard en plastique

autoclavable

Compris dans les accessoires standards livrés avec le broyeur

Pour le broyage cryogénique et les échantillons plus durs Cuve de broyage en acier inoxydable 316L autoclavable

Pour la vérification des polymères Cuve de broyage en verre autoclavable

Pour des échantillons huileux, pour la préparation d'échantillons sans BPA, résistant aux produits chimiques, résistant au lave-vaisselle jusqu'à 80° C

sans plastifiant

Cuve de broyage en Eastman Tritan Copolyester Pour les matériaux pas trop durs, déjà en petits morceaux, par exemple pour le contrôle de qualité dans l’alimentaire, le pharmaceutique, la chimie, la médecine légale et la pathologie Cuves de broyage à usage unique

Le récipient de broyage en plastique PC autoclavable, est inclus pour le broyage cryogénique et pour le broyage d'échantillons plus durs, nous proposons également un récipient de broyage en autoclavable acier inoxydable 316L.

Cuves de broyage

The grinding vessel made of plastic PC is included with the FRITSCH Knife Mill. The transparent grinding vessel made of scratch-resistant autoclavable plastic PC for the optimal observation of the comminution process is suitable for all standard samples.

| General specifications | |

| Material | Polycarbonate – PC |

| ISO/EN/DIN code | 7391-PC |

| Chemical composition | |

| Chemical Formula | HO-C6H4-R-C6H4-OH |

| Melting point | 150°C |

| Physical and mechanical properties | |

| Density | 1.20 g/cm³ |

| Hardness | HB 115 |

Explanations on hardness data

The grinding vessel made of autoclavable stainless steel 316L is suitable for cryogenic comminution and for the grinding of harder samples. Samples which are difficult to grind can be embrittled with liquid nitrogen directly in the grinding vessel made of stainless steel 316L. The sample materials remain 100 % cold.

For this purpose, please select the special lid, order no. 11.3220.00 with the easily exchangeable single-use sieve insert – the reliable protection against contamination. Single-use sieve inserts can be ordered with order no. 11.3224.00.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The grinding vessel made of Eastman Tritan Copolyester is suitable for the comminution of oily samples and for BPA-free sample preparation and which is plasticiserfree, resistant to chemicals and dishwasher-proof up to 80° C.

| General specifications | |

| Material | Eastman Tritan Copolyester |

| TX1001 | |

| General Properties | |

| food safe | |

| tasteless | |

| heat resistant up to 85°C | |

| colour stable | |

| resistant to chemicals | |

| dishwasher safe up to max. 80°C (80 cycles, with manual cleaning up to 300 cycles) | |

| free from bisphenol A (BPA) and free from plasticisers | |

| Physical and mechanical properties | |

| Density | 1.18 g/cm³ |

| Hardness | Rockwell 112 |

Explanations on hardness data

The grinding vessel made of glass is autoclavable and ideal for food-safe analysis and verification of polymers.

| General specifications | |

| Material | Borosilicate glass – 3.3 |

| Chemische Zusammensetzung | |

| Chemical Composition | Anteil % |

| SIO2 | 81 |

| B2O3 | 13 |

| Na2O + K2O | 4 |

| Al2O3 | 2 |

| Physical and mechanical properties | |

| Density | 2.23 g/cm³ |

Explanations on hardness data

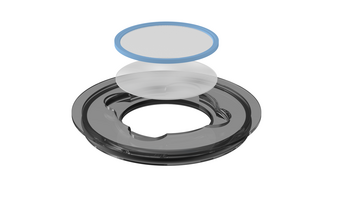

Couvercles pour les cuves de broyage

-

Couvercles pour les cuves de broyage

Pour les échantillons mous, moyennement durs, qui n'ont pas besoin d'être comprimé Couvercle standard en silicone autoclavable

Compris dans les accessoires standards livrés avec le broyeur

Pour les échantillons humides, liquides et visqueux pour réduire le volume de la chambre de broyage jusqu'à 0,54 litre

pour comprimer et détacher manuellement l'échantillon.

Idéal pour les petites quantités d'échantillons ou les matériaux difficiles à broyer pour obtenir un échantillon homogène dans une gamme étroite de granulométrie.

Système de couvercle Vario avec tige de poussée en plastique PP et poussoir de réduction autoclavable

Pour les échantillons solides, secs, pour réduire le volume de la chambre de broyage jusqu'à 0,54 litre pour comprimer ou détacher manuellement l'échantillon.

Idéal pour les petites quantités d'échantillons ou les matériaux difficiles à broyer pour obtenir un échantillon homogène dans une gamme étroite de granulométries.

Poussoir de réduction pour les échantillons secs et solidespour le système de couvercle Vario avec tige de poussée autoclavable

pour la fragmentation cryogénique avec tamis à usage unique Covercle spécial autoclavable

Pour le broyage cryogénique avec des inserts à tamis à usage unique Jeu d’inserts à tamis à usage unique

Disponible en standard avec un couvercle en silicone, un système Vario-Lid avec piston en plastique PP et un poussoir d'échantillon de réduction. Pour la fragmentation cryogénique, nous proposons un couvercle spécial avec un tamis à usage unique.

Des couvercles supplémentaires sont disponibles sur demande.

Couvercles pour les cuves de broyage

The included standard lid made of silicone is ideal for the comminution of soft, medium-hard samples which do not need to be compressed.

| General specifications | |

| Material | Silicone LR 3003/70 A/B |

| Physical and mechanical properties | |

| Density | 1.14 g/cm³ |

| Hardness | 70 Shore A |

Explanations on hardness data

The freely adjustable Vario-Lid system made of plastic PP for moist, liquid and viscous sample materials fulfils two important requirements at the same time: It can be used to reduce the grinding chamber volume down to 0.54 litre and to manually compress and loosen up the sample material.

Thus you always achieve a homogeneous sample in a narrow particle size range even for smaller sample quantities and for difficult to grind materials.

| General specifications | |

| Material | Polypropylene – PP 1502 |

| ISO/EN/DIN code | 1183 |

| Chemical composition | |

| Chemical Formula | C3H6 |

| Melting point | 163°C |

| Max. application temp. constant | 100° C |

| Max. application temp. briefly | 140° |

| Physical and mechanical properties | |

| Density | 0.903 g/cm³ |

| Hardness | Shore D70 |

Explanations on hardness data

The freely adjustable Vario-Lid system made of plastic PP for dry solid sample materials fulfils two important requirements at the same time: It can be used to reduce the grinding chamber volume down to 0.54 litre and to manually compress and loosen up the sample material.

Thus you always achieve a homogeneous sample in a narrow particle size range even for smaller sample quantities and for difficult to grind materials. The Vario-Lid system automatically returns rising liquids during the comminution and can be used for most sample materials.

| General specifications | |

| Material | Polypropylene – PP 1502 |

| ISO/EN/DIN code | 1183 |

| Chemical composition | |

| Chemical Formula | C3H6 |

| Melting point | 163°C |

| Max. application temp. constant | 100° C |

| Max. application temp. briefly | 140° |

| Physical and mechanical properties | |

| Density | 0.903 g/cm³ |

| Hardness | Shore D70 |

Explanations on hardness data

The special lid made of plastic PC for cryogenic comminution with single-use sieve insert for cryogenic comminution with the grinding vessel made of stainless steel 316L: order no. 11.3160.00.

For this lid we offer a set of single-use sieve inserts (set = 10 inserts): order no. 11.3224.00.

| General specifications | |

| Material | Polycarbonate – PC |

| ISO/EN/DIN code | 7391-PC |

| Chemical composition | |

| Chemical Formula | HO-C6H4-R-C6H4-OH |

| Melting point | 150°C |

| Physical and mechanical properties | |

| Density | 1.20 g/cm³ |

| Hardness | HB 115 |

Explanations on hardness data

For exchanging the sieve insert in the special lid for cryogenic grinding.

The single-use sieve insert guarantees reliable protection against contamination.

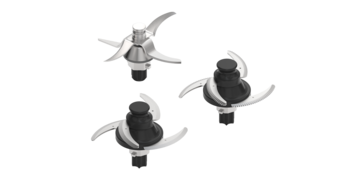

Couteaux

-

Couteaux

Pour presque tous les matériaux Couteau standard en acier inoxydable autoclavable

Compris dans les accessoires standards livrés avec le broyeur

For brittle , hard samples Couteau de hachoir en acier inoxydable autoclavable

Pour les échantillons fibreux, durs et osseux Couteau à hachoir avec lames dentées en acier inoxydable autoclavable

Pour un broyage sans métal Couteau à hachoir avec lames dentées Revêtement TIN

autoclavable

Le couteau standard en acier inoxydable peut être utilisé pour la fragmentation de presque tous les matériaux grâce à ses quatre lames et à une géométrie bien conçue. Pour broyer des échantillons particulièrement fibreux, durs ou nerveux, nous recommandons le couteau à lames dentées en acier inoxydable.

Des couteaux supplémentaires sont disponibles sur demande

Couteaux pour les cuves de broyage standard, les cuves de broyage en acier inoxydable et les cuves de broyage en plastique. Copolyester Eastman Tritan

The standard knife with four cutting edges of the PULVERISETTE 11 (included with the instrument) can be used for the comminution of nearly all materials. The specially curved knife blades achieve with up to 56,000 cutting processes per minute a homogeneous sample significantly faster than comparable instruments at the same grinding time and rotational speed. And in reverse mode, the knives enable a better thorough mixing if necessary.

| General specifications | |

| Material | Stainless steel – 1.4028 |

| ISO/EN/DIN code | X30Cr13 / DIN EN 10088-3 / AISI 420 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 87.74–85.65 |

| Carbon – C | 0.26–0.35 |

| Chromium – Cr | 12.00–14.00 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | 24 HRC |

Explanations on hardness data

The sickle knife made of stainless steel suitable for the comminution of brittle, hard samples.

| General specifications | |

| Material | Stainless steel – 1.4034 |

| ISO/EN/DIN code | X46Cr13 / DIN EN 10088-3 / AISI 420 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 87.07–82.93 |

| Carbon – C | 0.43–0.5 |

| Silicon – Si | 0–max. 1.0 |

| Manganese – Mn | 0–max. 1.0 |

| Phosphorus – P | 0–max 0.04 |

| Sulphur – S | 0–max. 0.03 |

| Chromium – Cr | 12.5–14.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | 245 HB |

Explanations on hardness data

The sickle knife with serrated blades made of stainless steel is especially suited for the comminution of especially fibrous, tough or sinewy samples.

| General specifications | |

| Material | Stainless steel – 1.4034 |

| ISO/EN/DIN code | X46Cr13 / DIN EN 10088-3 / AISI 420 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 87.07–82.93 |

| Carbon – C | 0.43–0.5 |

| Silicon – Si | 0–max. 1.0 |

| Manganese – Mn | 0–max. 1.0 |

| Phosphorus – P | 0–max 0.04 |

| Sulphur – S | 0–max. 0.03 |

| Chromium – Cr | 12.5–14.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | 245 HB |

Explanations on hardness data

The sickle knife with serrated blades, TiN-coated, is optimal for metal-free grinding.

Couteau pour cuve de broyage en verre

The sickle knife made of stainless steel suitable for the comminution of brittle, hard samples.

| General specifications | |

| Material | Stainless steel – 1.4034 |

| ISO/EN/DIN code | X46Cr13 / DIN EN 10088-3 / AISI 420 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 87.07–82.93 |

| Carbon – C | 0.43–0.5 |

| Silicon – Si | 0–max. 1.0 |

| Manganese – Mn | 0–max. 1.0 |

| Phosphorus – P | 0–max 0.04 |

| Sulphur – S | 0–max. 0.03 |

| Chromium – Cr | 12.5–14.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | 245 HB |

Explanations on hardness data

The sickle knife with serrated blades made of stainless steel is especially suited for the comminution of especially fibrous, tough or sinewy samples.

| General specifications | |

| Material | Stainless steel – 1.4034 |

| ISO/EN/DIN code | X46Cr13 / DIN EN 10088-3 / AISI 420 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 87.07–82.93 |

| Carbon – C | 0.43–0.5 |

| Silicon – Si | 0–max. 1.0 |

| Manganese – Mn | 0–max. 1.0 |

| Phosphorus – P | 0–max 0.04 |

| Sulphur – S | 0–max. 0.03 |

| Chromium – Cr | 12.5–14.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | 245 HB |

Explanations on hardness data

The sickle knife with serrated blades, TiN-coated, is optimal for metal-free grinding.

Cuves de broyage à usage unique

Les cuves de broyage à usage unique sont idéales pour une utilisation dans le domaine pharmaceutique, la criminalogie et pathologie, l'extraction d'ARN / ADN, la bactériologie et la chimie.

Cuves de broyage à usage unique

Adapter for single-use grinding vessel 40 ml and 100 ml volume.

For the use of the Knife Mill PULVERISETTE 11 in single-use technology, we have developed an adapter for single-use grinding vessels 40 ml and 100 ml volume for the comminution of not too hard materials, which are available in small pieces. Your advantage: safe protection against cross contamination, no need for cleaning and the sample can be stored in the single-use grinding vessels.

Ideal for use in food quality control, pharmacy, chemistry, forensics and pathology.

Set of single-use grinding vessels 40 ml volume made of plastic PP (set = 10 pieces).

The single-use grinding vessels are ideal for use in food quality control, pharmacy, chemistry, forensics and pathology.

| General specifications | |

| Material | Polypropylene – PP 1502 |

| ISO/EN/DIN code | 1183 |

| Chemical composition | |

| Chemical Formula | C3H6 |

| Melting point | 163°C |

| Max. application temp. constant | 100° C |

| Max. application temp. briefly | 140° |

| Physical and mechanical properties | |

| Density | 0.903 g/cm³ |

| Hardness | Shore D70 |

Explanations on hardness data

Set single-use grinding vessels 40 ml volume made of plastic PP (set = 100 pieces).

The single-use grinding vessels are ideal for the use in in food quality control, pharmacy, chemistry, forensics and pathology.

| General specifications | |

| Material | Polypropylene – PP 1502 |

| ISO/EN/DIN code | 1183 |

| Chemical composition | |

| Chemical Formula | C3H6 |

| Melting point | 163°C |

| Max. application temp. constant | 100° C |

| Max. application temp. briefly | 140° |

| Physical and mechanical properties | |

| Density | 0.903 g/cm³ |

| Hardness | Shore D70 |

Explanations on hardness data

Set of single-use grinding vessels 100 ml volume made of plastic PP (set = 10 pieces).

The single-use grinding vessels are ideal for the use in food quality control, pharmacy, chemistry, forensics and pathology.

| General specifications | |

| Material | Polypropylene – PP 1502 |

| ISO/EN/DIN code | 1183 |

| Chemical composition | |

| Chemical Formula | C3H6 |

| Melting point | 163°C |

| Max. application temp. constant | 100° C |

| Max. application temp. briefly | 140° |

| Physical and mechanical properties | |

| Density | 0.903 g/cm³ |

| Hardness | Shore D70 |

Explanations on hardness data

Set single-use grinding vessels 100 ml volume made of plastic PP (set = 100 pieces).

The single-use grinding vessels are ideal for use in food quality control, pharmacy, chemistry, forensics and pathology.

| General specifications | |

| Material | Polypropylene – PP 1502 |

| ISO/EN/DIN code | 1183 |

| Chemical composition | |

| Chemical Formula | C3H6 |

| Melting point | 163°C |

| Max. application temp. constant | 100° C |

| Max. application temp. briefly | 140° |

| Physical and mechanical properties | |

| Density | 0.903 g/cm³ |

| Hardness | Shore D70 |

Explanations on hardness data

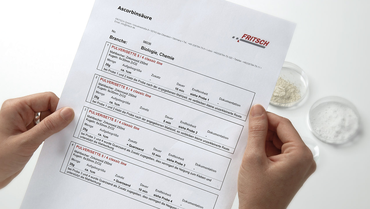

Choisissez le Logiciel

Le logiciel P-11Control pour Windows: pour le contrôle automatique du broyeur via port USB, pour l’édition, la sauvegarde et la gestion des SOPs avec le générateur de rapports de broyage.

Logiciel P-11Control pour Windows

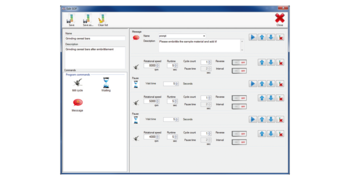

The Software P-11Control for Windows: for automatic control of the mill via USB, for editing, saving and managing of the SOPs with grinding report generator.

With the software P-11Control, the mill can be controlled via the integrated USB port. SOPs can be edited, saved and managed directly on the connected laptop via drag & drop. Reversion-proof grinding reports can be created, archived quickly and easily with the integrated report generator.

The software P-11Control offers a data interface for the connection to your laboratory database.

Autres accessoires

En outre, un racloir, un accouplement de lame de rechange et une certification pour votre mixeur homogénéisateur à couteaux PULVERISETTE 11 sont également disponibles.

Autres accessoires

The scraper made of robust plastic is a useful helper in the laboratory and can be utilized to remove sample material completely from the grinding vessel.

| General specifications | |

| Material | PUR-Elastomer – TPU 93A |

| Material number | 2634 |

| Chemical composition | |

| Chemical Formula | C3H7NO2 |

| Physical and mechanical properties | |

| Density ISO 1183 | 1.24 |

| Hardness Shore (A/D) | A93 |

Explanations on hardness data

A replacement knife coupling for the protection of the knife holder is already included in the delivery of the instrument. We recommend replacing the knife coupling after 200 hours of operation to avoid damage to the instrument.

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Knife Mill PULVERISETTE 11.