Divers Broyeurs à couteaux

AUTRES GROUPES DE PRODUITS

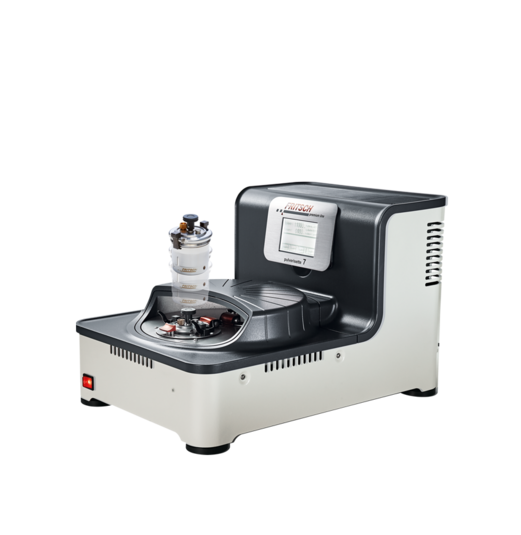

Broyeur à couteaux mini

PULVERISETTE 29

The Mini Cutting Mill PULVERISETTE 29 is equipped with 5 sample cups 100 ml.

Please note: In order to work with the Mini Cutting Mill PULVERISETTE 29 you require the following accessories:

- Funnel

- Cutting tool set

- Sieve inserts

Optional

- Set of sample cups 100 ml = 100 sample cups

- Certification

Funnel

For the PULVERISETTE 29 select our funnel with pusher to easily feed your sample materials.

FUNNEL

The funnel with sample pusher with an inner diameter of 27 mm, enables a good handling and an outstanding material feeding for a variety of materials.

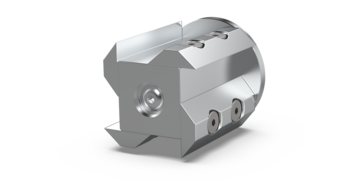

CUTTING TOOL SET made of hardened stainless steel

-

Material data for cutting tool sets and application recommendation

Material and rotor type Main component of material Abrasion resistance Density g/cm³ Suitable for comminution of Hardened, stainless steel Fe - Cr fairly good 7.7 Standard rotor with V-cutting edges and fixed knives,

order no. 45.5100.00medium-hard, brittle samples and for tough-elastic materials and films Hardmetal tungsten carbide WC very good 12.4 Rotor with V-cutting edges and fixed knives, order no 45.5370.00

Disk milling cutter rotor with indexable inserts and fixed knives,

order no. 45.5200.00hard, abrasive samples and hard-tough materials

hard, abrasive samples and scrap circuit board with glass fibre residue and copper cableHardened, stainless steel

Fe - Cr fairly good 7.7 Rotor with straight cutting edges and fixed knives,

order no. 45.5185.00medium-hard, brittle samples and for easily cut material, such as hay, straw, fibrous or biological materials

We offer a rotor with straight cutting edges and straight knives made of stainless steel for our Mini Mill.

CUTTING TOOL SET MADE OF hardened Stainless Steel

The rotor made of hardened, stainless steel with straight cutting edges which run parallel to the fixed knives is suitable for a variety of materials. The rotor knives may be turned, since they have 2 cutting edges. Your advantage: doubling the life span of your rotor knives.

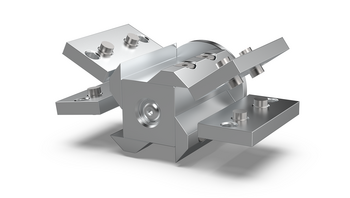

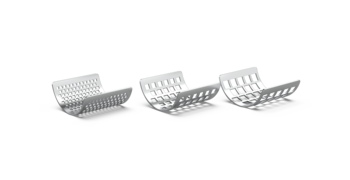

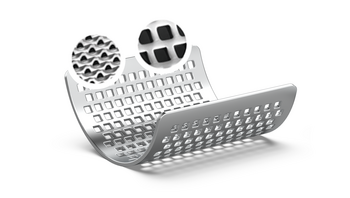

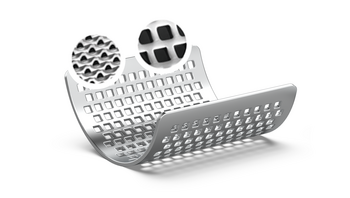

Sieve inserts made of stainless steel 316L

Sieve inserts determine the fineness of a sample. Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band. Sieve inserts are also available in further perforations.

Sieve inserts MADE OF STAINLESS STEEL 316L

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

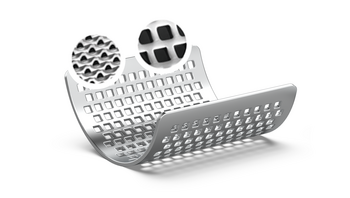

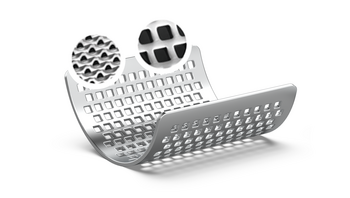

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

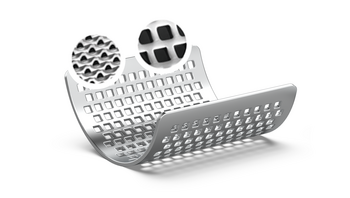

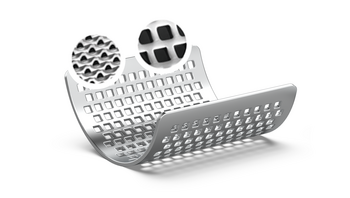

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving of medium fineness with a narrow grain band.

Sieve inserts determine the final fineness of a sample.

Sieve inserts with square and trapezoidal perforations are offered. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with square and trapezoidal perforations are offered. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

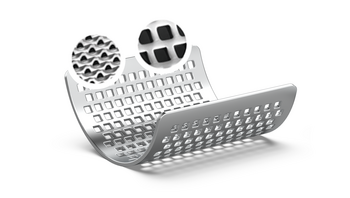

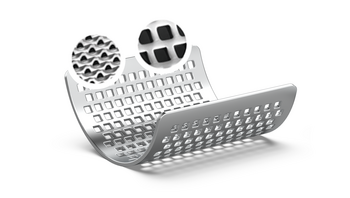

Sieve inserts determine the final fineness of a sample.

Sieve inserts with square and trapezoidal perforations are offered. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Accessory

For easy and hygienic sample collection, the Mini Cutting Mill PULVERISETTE 29 is delivered with 5 sample cups 100 ml. Sample cups 100 ml can be ordered separately.

ACCESSORY

Set of sample cups 100 ml = 100 sample cups

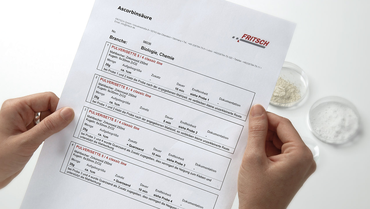

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation not included) for the independent utilization for the support of instrument qualification in the quality management system for our Mini-Cutting Mill PULVERISETTE 19.

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Mini Cutting Mill PULVERISETTE 29.