Divers Broyeurs à couteaux

AUTRES GROUPES DE PRODUITS

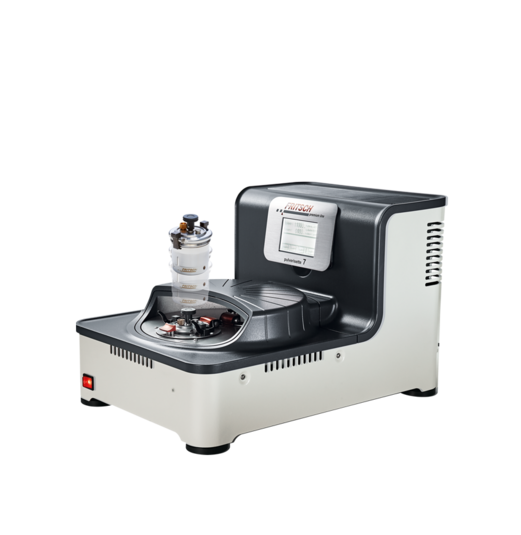

Broyeur à couteaux

PULVERISETTE 15

Configurez votre broyeur à couteaux PULVERISETTE 15 à votre application.

Parmi les nombreux accessoires, choisissez au moins une trémie d'application, un jeu d'outils de coupe, un tamis et un récipient collecteur.

Trémie d'alimentation

Trémie d’alimentation pour échantillons longs et en vrac en plastique, ou

trémie étanche en acier inoxydable avec sas et coulisseau en plastique

Jeu d'outils de coupe

Rotor avec couteaux droits et contre-couteaux en acier à outil ou en acier à outil sans chrome

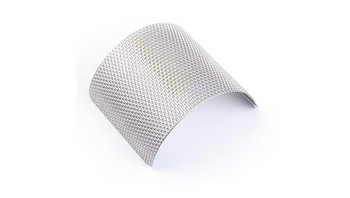

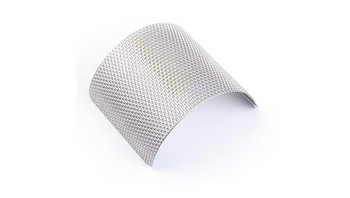

Tamis

Tamis à perforation trapézoïdale ou carrée en acier inoxydable 316L ou en acier sans chrome DC01

Récipient collecteur

Récipient collecteur de 3,5 litres ou récipient collecteur pour grandes quantités de 60 litres avec tuyau filtrant

Accessoires disponibles en option

Support : support universel

TRÉMIES D'ALIMENTATION

Vous pouvez équiper la PULVERISETTE 15 d'une trémie d'alimentation en plastique pour matériaux longs et en vrac pouvant être introduits dans toute leur longueur, ou bien d'une trémie étanche en acier inoxydable avec sas et coulisseau en plastique destinée à tous les autres matériaux.

Trémies d'alimentation

With the FRITSCH standard funnel free-flowing bulk solids as well as straw, films or similar materials can be inserted at full length. Both ends of the plunger of the funnel for long and bulk solids can be utilised: the small end for adding of long goods and the wide end for bulk solids.

The protected funnel made of stainless steel with plastic sample pusher enables due to the sample pusher a good handling and an outstanding material feeding.

RÉCIPIENTS COLLECTEURS

Un récipient collecteur de 3,5 litres est disponible. Nous recommandons d'utiliser le récipient collecteur de 10 litres avec tuyau filtrant pour le broyage de grande quantités.

RÉCIPIENTS COLLECTEURS

For smaller samples this collecting vessel 3.5 litres is recommended.

For grinding large quantities this collecting vessel with a capacity of 60 litres and filter hose is recommended.

Ideal: The FRITSCH Universal Support Stand offers for your Cutting Mill PULVERISETTE 15 even with the 60 l collecting vessel and filter hose a solid, space-saving and spatially variable basis - order no. 45.5820.00.

JEU D'OUTILS DE COUPE en acier à outil

-

Caractéristiques des jeux d'outils de coupe et applications recommandées

Matériau et type de rotor Composant principal du matériau Résistance à l'abrasion Densité en g/cm³ Convient au broyage de acier à outil

Fe - Cr relativement bonne 7,85 Rotor avec couteaux droits et

contre-couteaux

référence 15.4603.00échantillons mi-durs, cassants, et matériaux facilement sectionnables de type foin, paille, matériaux fibreux et biologiques acier à outil sans chrome Fe relativement bonne 7,8 Rotor avec couteaux droits et

contre-couteaux

référence 15.4602.00recommandé surtout pour la préparation d'échantillons selon RoHS, par exemple pour prouver la présence de chrome hexavalent et pour l'analyse XRF

Le rotor avec couteaux droits positionnés parallèlement aux contre-couteaux, est particulièrement adapté aux matériaux facilement sectionnables de type foin, paille, matériaux fibreux et biologiques.

JEU D'OUTILS DE COUPE EN ACIER À OUTIL

The rotor with straight cutting edges which run parallel to the fixed knives is especially suitable for easily cuttable materials like hay, straw, fibrous and biological materials. The rotor knives have two cutting edges and can simply be turned when one side is used up. Your advantage: double service life.

For the sample preparation according to RoHS (for the poof of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets made of chromium-free tool steel.

| 1. Rotorknives | |

| General specifications | |

| Material | Tool steel – 1.2379 |

| ISO/EN/DIN code | X155CrVMo12/1 / 59350 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 85.79 – 82.14 |

| Carbon – C | 1.45 – 1.6 |

| Silicon – Si | 0.1 - 0.6 |

| Manganese – Mn | 0.2 – 0.6 |

| Phosphorus – P | 0.03 |

| Sulphur – S | 0.03 |

| Chromium – Cr | 11 – 13 |

| Molybdenum – Mo | 0.7 - 1 |

| Tungsten – W | 0.7 - 1 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ ; |

| Hardness | 58-60 HV |

| 2. Rotor body | |

| General specifications | |

| Material | Construction steel – 1.0037 – FeP03 |

| ISO/EN/DIN code | S235 JR |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 98.34 |

| Carbon – C | 0.17 |

| Manganese – Mn | 1.4 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Chromium – Cr | 1.660 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 20-95 HV |

Explanations on hardness data

TAMIS en acier inoxydable 316L

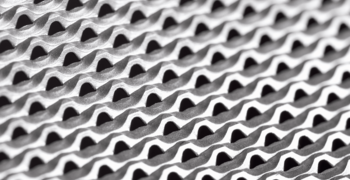

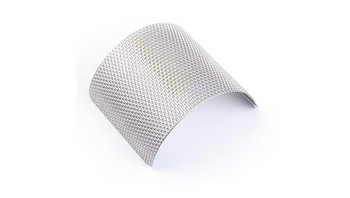

Les tamis déterminent la granulométrie finale de l'échantillon. Des tamis à perforation trapézoïdale et à perforation carrée sont disponibles. Les cassettes à tamis à perforation trapézoïdale provoquent une fragmentation supplémentaire résultant du cisaillement plus important. Les cassettes à tamis à perforation carrée sont recommandées pour fragmenter des matériaux cassants et des matériaux de finesse moyenne à plage granulométrique étroite.

Les tamis sont aussi disponibles avec d'autres perforations.

TAMIS EN ACIER INOXYDABLE 316L

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving of medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample. Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve inserts determine the final fineness of a sample

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF-analysis, we recommend FRITSCH sieve inserts made of chromium-free steel DC01.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

ACCESSOIRES pour broyage SANS CHROME

-

Caractéristiques des jeux d'outils de coupe et applications recommandées

Matériau et type de rotor Composant principal du matériau Résistance à l'abrasion Densité en g/cm³ Convient au broyage de acier à outil

Fe - Cr relativement bonne 7,85 Rotor avec couteaux droits et

contre-couteaux

référence 15.4603.00échantillons mi-durs, cassants, et matériaux facilement sectionnables de type foin, paille, matériaux fibreux et biologiques acier à outil sans chrome Fe relativement bonne 7,8 Rotor avec couteaux droits et

contre-couteaux

référence 15.4602.00recommandé surtout pour la préparation d'échantillons selon RoHS, par exemple pour prouver la présence de chrome hexavalent et pour l'analyse XRF

Lorsqu'une préparation d'échantillon conforme à RoHS (destinée par exemple à prouver la présence de chrome hexavalent) ou à des analyses XRF doit impérativement assurer une fragmentation garantie sans chrome, les jeux d'outils de coupe FRITSCH en acier à outil sans chrome et les tamis en acier sans chrome DC01 vous donnent la sécurité nécessaire.

JEU D'OUTILS DE COUPE en acier à outil SANS CHROME

The rotors made of chromium-free tool steel are especially recommended for the sample preparation according to RoHS and for the XRF-analysis. If a chromium-free size reduction is required for sample preparation according to RoHS – for example for verification of hexavalent chromium – or for XRF analysis, FRITSCH cutting tool sets of chromium-free tool steel offer this absolute assurance. Because for FRITSCH Cutting Mills, the fixed knives are always of the same material as the cutting edges of the rotor.

The chromium-free tool steel rotor with straight cutting edges which run parallel to the fixed knives is suitable for easily cut material, such as hay, straw, fibrous or biological materials.

The rotor knives can be turned, since they have two cutting edges. Your advantage: doubling the service life of the rotor knives.

For all other applications the rotor of tool steel can be used, because of its hardness and top resistance against abrasion.

| 1. Rotor knives | |

| General specifications | |

| Material | Chromium-free tool steel – 1.1740 |

| ISO/EN/DIN code | C60W3 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 98.63 – 98.08 |

| Carbon – C | 0.55 – 0.65 |

| Silicon – Si | 0.15 – 0.4 |

| Manganese – Mn | 0.6 – 0.8 |

| Phosphorus – P | < 0.035 |

| Sulphur – S | < 0.035 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | 50 - 55 HRC |

| 2. Rotor body | |

| General specifications | |

| Material | Construction steel – 1.0037 |

| ISO/EN/DIN code | S235- JR formerly St 37 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 98.34 |

| Carbon – C | 0.17 |

| Silicon – Si | 0.3 |

| Manganese – Mn | 1.4 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | ~ 65 HRA |

Explanations on hardness data

TAMIS EN ACIER SANS CHROME DC01

The sieve inserts made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF- analysis. For all other applications sieve inserts made of stainless steel may be used since these are harder and more resilient against abrasion.

Sieve inserts determine the fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

The sieve inserts made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF- analysis. For all other applications sieve inserts made of stainless steel may be used since these are harder and more resilient against abrasion.

Sieve inserts determine the fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

The sieve inserts made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF- analysis. For all other applications sieve inserts made of stainless steel may be used since these are harder and more resilient against abrasion.

Sieve inserts determine the fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve inserts with trapezoidal perforations improve size reduction through extra shearing action. Sieve inserts with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

SUPPORT UNIVERSEL

Le support universel FRITSCH représente une base très stable, peu encombrante et à géométrie variable pour le broyeur.

SUPPORT

Stand for free installation of the following devices:

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm large

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm Large

Cross Beater Mill PULVERISETTE 16 with grinding insert made of cast iron

Cross Beater Mill PULVERISETTE 16 with grinding insert made of stainless steel

The PULVERISETTE 19 is shown as an example in the photo.

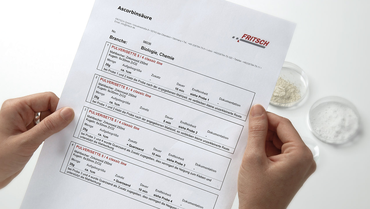

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Cutting Mill PULVERISETTE 15.