Divers Broyeurs à rotor / à marteaux

AUTRES GROUPES DE PRODUITS

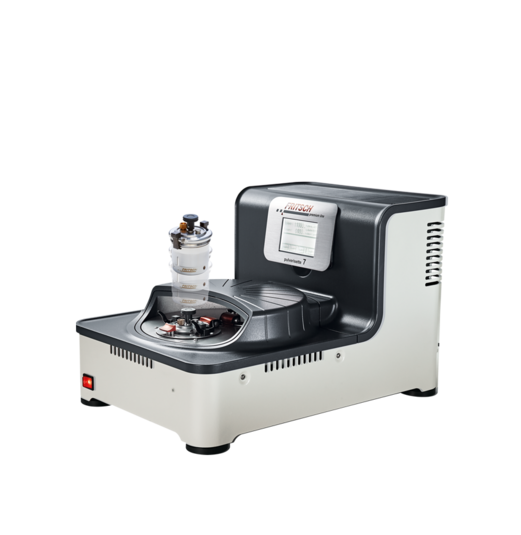

Broyeur rapide à rotor

PULVERISETTE 14

classic lineLe broyeur centrifuge PULVERISETTE 14 classic line est fourni avec un récipient collecteur et un couvercle.

Veuillez tenir compte des points suivants : Pour pouvoir travailler avec le broyeur rapide à rotor PULVERISETTE 14, il doit être équipé d'un rotor et d'au moins un tamis annulaire.

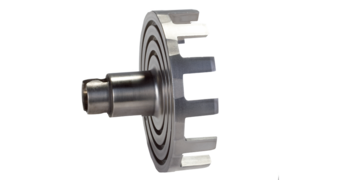

ROTORS À IMPACT EN ACIER INOXYDABLE

Les rotors à impact à usage intensif, résistants à l'usure de PULVERISETTE 14 classic line en acier inoxydable, sont adaptés à toutes les applications standard de broyage de matières molles à mi-dures, cassantes, fibreuses, allant du calcaire jusqu'aux végétaux. Les différentes tâches de broyage sont possibles grâce aux rotors à 8, 12 et 24 dents.

ROTORS À IMPACT EN ACIER INOXYDABLE

For fast, grinding of fibrous substances.

The following impact rotors made of stainless steel are offered:

12-rib rotor for the grinding of materials with feed particle sizes < 10 mm

24 rib rotor for the grinding of fine materials with feed particle sizes < 5 mm with highest air throughput

| General specifications | |

| Material | Stainless steel – 1.4057 |

| ISO/EN/DIN code | X17CrNi16-2 |

| AISI code | 431 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 77.7–80.8 |

| Carbon – C | 0.12–0.22 |

| Silicon – Si | ≤ 1.0 |

| Manganese – Mn | ≤ 1.5 |

| Chromium – Cr | 15–17 |

| Nickel – Ni | 1.5–2.5 |

| Phosphorus – P | ≤ 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7g/cm³ |

| Hardness | 295 HB |

Explanations on hardness data

For the grinding of materials with feed particle sizes < 10 mm.

The following impact rotors made of stainless steel are available:

8-rib rotor for the fast grinding of fibrous substances

24-rib rotor: for the grinding of fine materials with feed particle sizes < 5 mm with highest air throughput

| General specifications | |

| Material | Stainless steel – 1.4057 |

| ISO/EN/DIN code | X17CrNi16-2 |

| AISI code | 431 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 77.7–80.8 |

| Carbon – C | 0.12–0.22 |

| Silicon – Si | ≤ 1.0 |

| Manganese – Mn | ≤ 1.5 |

| Chromium – Cr | 15–17 |

| Nickel – Ni | 1.5–2.5 |

| Phosphorus – P | ≤ 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7g/cm³ |

| Hardness | 295 HB |

Explanations on hardness data

For the grinding of fine materials with feed particle sizes < 5 mm with highest air throughput.

The following impact rotors made of stainless steel are available:

8-rib rotor for the fast grinding of fibrous substances

12-rib rotor: for the grinding of samples with feed particle sizes of < 10 mm

| General specifications | |

| Material | Stainless steel – 1.4057 |

| ISO/EN/DIN code | X17CrNi16-2 |

| AISI code | 431 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 77.7–80.8 |

| Carbon – C | 0.12–0.22 |

| Silicon – Si | ≤ 1.0 |

| Manganese – Mn | ≤ 1.5 |

| Chromium – Cr | 15–17 |

| Nickel – Ni | 1.5–2.5 |

| Phosphorus – P | ≤ 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7g/cm³ |

| Hardness | 295 HB |

Explanations on hardness data

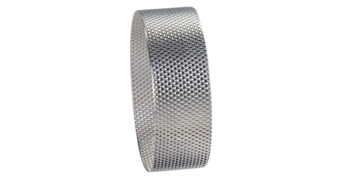

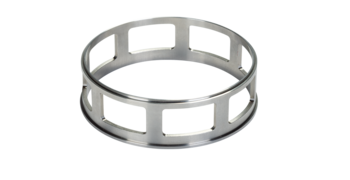

TAMIS ANNULAIRES EN ACIER INOXYDABLE 316L

-

Tamis annulaires

Broyage rapide de matériaux de dureté moyenne ou mous Tamis annulaire à perforation trapézoïdale

pour effet de cisaillementBroyage rapide de matériaux cassantes pour obtenir des finesses moyennes Tamis annulaire à perforation carrée

pour un plus grand débit et moins de résidus d'échantillon grâce à la surface de tamisage plus grande et ouverte

Tamis annulaire à perforation ronde

pour une gamme étroite de tailles de particulesCharges extrêmes Annneau de tamisage avec anneaux de renforcement

Les tamis annulaires à usage intensif et résistants à l'usure de PULVERISETTE 14 classic line, en acier inoxydable, sont adaptés à toutes les applications standard de fragmentation de matières molles à mi-dures, cassantes, fibreuses, allant du calcaire jusqu'aux végétaux. Les tamis annulaires sont disponibles en version perforation trapézoïdale, perforation carrée ou perforation ronde, de 0,08 à 6 mm, destinés à différentes tâches de broyage.

TAMIS ANNULAIRES EN ACIER INOXYDABLE 316L

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with square perforation are recommended for the comminution of brittle materials for achieving medium fineness, but often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with round perforation are recommended for reduction of brittle materials for achieving medium fineness in a smaller grain band.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample. e.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve rings determine the final fineness of the sample.

Sieve rings with round and square perforations are recommended for the comminution of brittle materials for achieving medium finenesses.

Sieve rings with round perforation achieve during comminution a smaller grain band.

Sieve rings with square perforation often achieve a higher throughput and the sample residue is less compared to sieve rings with round perforation.

Sieve rings with trapezoidal perforations are suitable for fast comminution of medium hard to soft materials and improve size reduction through extra shearing action.

Sieve rings with reinforced edges with trapezoidal perforation for heavy duty size reduction are also offered.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

TAMIS ANNULAIRES À BAGUES DE RENFORT POUR USAGE INTENSIF; EN ACIER INOXYDABLE 316L

Des tamis annulaires à perforation trapézoïdale pouvant atteindre 2 mm et bagues de renfort permettent de réaliser des broyages à contraintes particulièrement importantes.

TAMIS ANNULAIRES À BAGUES DE RENFORT POUR USAGE INTENSIF; EN ACIER INOXYDABLE

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

For heavy duty use.

Sieve rings determine the end fineness of the sample.

Sieve rings for heavy duty use with reinforced edges are offered with trapezoidal perforations.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

ACCESSOIRES DE BROYAGE SANS MÉTAUX NI MÉTAUX LOURDS ET PRÉPARATION D'ÉCHANTILLON SELON ROHS

-

BROYAGE SANS MÉTAUX NI MÉTAUX LOURDS

Pour le broyage de végétaux, de graines céréalières ou de produits alimentaires sélectionnez un rotor à 12 batteurs en titane, un tamis annulaire avec des bagues de renfort également en titane, tamis à sélectionner en fonction de la finesse finale recherchée Pour le broyage de riz, de bois, de cuirs ou de matériaux synthétiques sélectionnez un rotor et un tamis annulaire avec un revêtement en TiN, pour les échantillons présentant des morceaux < 10 mm, utilisez un rotor à 12 batteurs, pour des morceaux < 5 mm prendre un rotor à 24 batteurs Pour la préparation d‘échantillons dans le cadre de la directive RoHS Sélectionnez un rotor et un tamis annulaire avec un revêtement en TiN pour les échantillons présentant des morceaux < 10 mm, utilisez un rotor à 12 batteurs, pour des morceaux < 5 mm prendre un rotor à 24 batteurs

Pour le broyage sans métaux ni métaux lourds et la préparation d'échantillons conformes à la directive RoHS, commandez un broyeur rapide à rotor PULVERISETTE 14 classic line avec un couvercle et un récipient collecteur à revêtement PTFE. Choisissez aussi un rotor à impact et un tamis annulaire.

ACCESSOIRES DE BROYAGE SANS MÉTAUX NI MÉTAUX LOURDS ET PRÉPARATION D'ÉCHANTILLON SELON ROHS

Heavy-metal- and iron-free grinding

For both: heavy-metal-free and iron-free grinding you can order your PULVERISETTE 14 classic line with a PTFE-coated lid and collecting vessel:

For grinding soft samples like leaves, grain and soft foods select additionally a 12-rib impact rotor and a sieve ring with reinforced edges made of pure titanium with a matching perforation for the desired final fineness.

For grinding medium-hard samples like rice, wood, leather or plastics select additionally a sieve ring TiN-coated and for feed particle sizes < 10 mm a 12-rib rotor and for feed particle sizes < 5 mm a 24-rib rotor TiN-coated.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | |

| Element | Formula |

| Polytetrafluoroethylene | C 2F4 |

| Melting point | 327° C |

| Max. application temp. constant | 260° C |

| Max. application temp. briefly | 300° C |

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

For heavy-metal- and iron-free grinding of soft materials such as leaves, grains and soft foods.

Order with the 12-ribs pure titanium impact rotor, a pure titanium sieve ring with reinforced edges, available with 0.2 mm, 0.5 mm, 1 mm and 2 mm trapezoidal perforations.

Also needed is a PTFE-coated lid and PTFE-coated collecting pan, order no. 14.3750.00.

| General specifications | |

| Material | Pure titanium – 3.7035 – Ti 2 |

| ISO/EN/DIN code | DIN 17861 |

| Chemical composition | |

| Element | Share % |

| Titanium – Ti | 99.4 – 99.5 |

| Oxygen – O | 0.18 |

| Nitrogen – N | 0.05 |

| Carbon – C | 0.06 |

| Hydrogen – H | 0.013 |

| Iron - Fe | 0.2 |

| Physical and mechanical properties | |

| Density | 4.5 g/cm³ |

| Hardness / Brinell guide value HB 30 | 150 Brinell hardness |

Explanations on hardness data

For heavy duty loads for the heavy-metal-free and iron-free grinding of soft materials such as leaves, grains and soft foods.

Sieve rings determine the end fineness of the sample. Pure titanium sieve rings with reinforced edges for heavy duty loads are offered with trapezoidal perforations. Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings made of pure titanium with 0.5 mm, 1 mm and 2 mm trapezoidal perforation and an impact rotor with 12 ribs made of pure titanium can be ordered.

Also a PTFE-coated lid and collecting pan are available as a set (Order No. 14.3750.00).

| General specifications | |

| Material | Pure titanium – 3.7035 – Ti 2 |

| ISO/EN/DIN code | DIN 17861 |

| Chemical composition | |

| Element | Share % |

| Titanium – Ti | 99.4 – 99.5 |

| Oxygen – O | 0.18 |

| Nitrogen – N | 0.05 |

| Carbon – C | 0.06 |

| Hydrogen – H | 0.013 |

| Iron - Fe | 0.2 |

| Physical and mechanical properties | |

| Density | 4.5 g/cm³ |

| Hardness / Brinell guide value HB 30 | 150 Brinell hardness |

Explanations on hardness data

For heavy duty loads for the heavy-metal-free and iron-free grinding of soft materials such as leaves, grains and soft foods.

Sieve rings determine the end fineness of the sample. Pure titanium sieve rings with reinforced edges for heavy duty loads are offered with trapezoidal perforations. Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings made of pure titanium with 0.2 mm, 1 mm and 2 mm trapezoidal perforation and an impact rotor with 12 ribs made of pure titanium can be ordered.

Also a PTFE-coated lid and collecting pan are available as a set (Order No. 14.3750.00).

| General specifications | |

| Material | Pure titanium – 3.7035 – Ti 2 |

| ISO/EN/DIN code | DIN 17861 |

| Chemical composition | |

| Element | Share % |

| Titanium – Ti | 99.4 – 99.5 |

| Oxygen – O | 0.18 |

| Nitrogen – N | 0.05 |

| Carbon – C | 0.06 |

| Hydrogen – H | 0.013 |

| Iron - Fe | 0.2 |

| Physical and mechanical properties | |

| Density | 4.5 g/cm³ |

| Hardness / Brinell guide value HB 30 | 150 Brinell hardness |

Explanations on hardness data

For heavy duty loads for the heavy-metal-free and iron-free grinding of soft materials such as leaves, grains and soft foods.

Sieve rings determine the end fineness of the sample. Pure titanium sieve rings with reinforced edges for heavy duty loads are offered with trapezoidal perforations. Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings made of pure titanium with 0.2 mm, 0.5 mm and 2 mm trapezoidal perforation and an impact rotor with 12 ribs made of pure titanium can be ordered.

Also a PTFE-coated lid and collecting pan are available as a set (Order No. 14.3750.00).

| General specifications | |

| Material | Pure titanium – 3.7035 – Ti 2 |

| ISO/EN/DIN code | DIN 17861 |

| Chemical composition | |

| Element | Share % |

| Titanium – Ti | 99.4 – 99.5 |

| Oxygen – O | 0.18 |

| Nitrogen – N | 0.05 |

| Carbon – C | 0.06 |

| Hydrogen – H | 0.013 |

| Iron - Fe | 0.2 |

| Physical and mechanical properties | |

| Density | 4.5 g/cm³ |

| Hardness / Brinell guide value HB 30 | 150 Brinell hardness |

Explanations on hardness data

For heavy duty loads for the heavy-metal-free and iron-free grinding of soft materials such as leaves, grains and soft foods.

Sieve rings determine the end fineness of the sample. Pure titanium sieve rings with reinforced edges for heavy duty loads are offered with trapezoidal perforations. Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings made of pure titanium with 0.2 mm, 0.5 mm and 1 mm trapezoidal perforation and an impact rotor with 12 ribs made of pure titanium can be ordered.

Also a PTFE-coated lid and collecting pan are available as a set (Order No. 14.3750.00).

| General specifications | |

| Material | Pure titanium – 3.7035 – Ti 2 |

| ISO/EN/DIN code | DIN 17861 |

| Chemical composition | |

| Element | Share % |

| Titanium – Ti | 99.4 – 99.5 |

| Oxygen – O | 0.18 |

| Nitrogen – N | 0.05 |

| Carbon – C | 0.06 |

| Hydrogen – H | 0.013 |

| Iron - Fe | 0.2 |

| Physical and mechanical properties | |

| Density | 4.5 g/cm³ |

| Hardness / Brinell guide value HB 30 | 150 Brinell hardness |

Explanations on hardness data

Heavy-metal- and iron-free grinding: For grinding medium-hard samples like rice, wood, leather or plastics for feed particle sizes < 10 mm.

Along with the TiN-coated 12-rib rotor, additionally select a sieve ring also TiN-coated (available with 0.12 mm, 0.2 mm, 0.5 mm und 1 mm trapezoidal perforation).

For feed particle sizes < 5 mm, a TiN-coated 24-rib rotor is available: order no. 44.4240.00.

RoHS: For sample preparation according to RoHS – such as for verification of hexavalent chromium, for feed particle sizes < 10 mm.

Select along with the TiN-coated 12 rib-rotor, a sieve ring also TiN-coated (available with 0.12 mm, 0.2 mm, 0.5 mm und 1 mm trapezoidal perforation).

For feed particle sizes < 5 mm, a TiN-coated 24-rib rotor is available: order no. 44.4240.00.

Please note: for heavy-metal-iron-free grinding and sample preparation according to RoHS, a PTFE-coated lid and collecting vessel are always required, order no. 14.3750.00.

| General specifications | |

| Material | Titanium nitride – TiN |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Titanium nitride TiN | 100 |

Heavy-metal- and iron-free grinding: For grinding medium-hard samples like rice, wood, leather or plastics for feed particle sizes < 5 mm.

Along with the TiN-coated 24-rib rotor, additionally select a sieve ring also TiN-coated (available with 0.12 mm, 0.2 mm, 0.5 mm und 1 mm trapezoidal perforation).

For feed particle sizes < 10 mm, a TiN-coated 12-rib rotor is available: order no. 44.4120.00.

RoHS: For sample preparation according to RoHS – such as for verification of hexavalent chromium, for feed particle sizes < 5 mm.

Select along with the TiN-coated 24 rib-rotor, a sieve ring also TiN-coated (available with 0.12 mm, 0.2 mm, 0.5 mm und 1 mm trapezoidal perforation).

For feed particle sizes < 10 mm, a TiN-coated 12-rib rotor is available: order no. 44.4120.00.

Please note: for heavy-metal-iron-free grinding and sample preparation according to RoHS, a PTFE-coated lid and collecting vessel are always required, order no. 14.3750.00.

| General specifications | |

| Material | Titanium nitride – TiN |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Titanium nitride TiN | 100 |

For heavy-metal and iron-free grinding of medium-hard materials such as rice, wood, leather or plastics and for sample preparation according to RoHS – such as for verification of hexavalent chromium.

Sieve rings determine the end fineness of the sample.

Sieve rings TiN-coated are offered with trapezoidal perforation. The trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings TiN-coated with 0.2 mm, 0.5 mm and 1 mm trapezoidal perforations and impact rotors with 12 and 24 ribs, TiN-coated can be ordered.

Please note: for heavy-metal-iron-free grinding and sample preparation according to RoHS, a PTFE-coated lid and collecting vessel are always required, order no. 14.3750.00.

| General specifications | |

| Material | Titanium nitride – TiN |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Titanium nitride TiN | 100 |

For heavy-metal and iron-free grinding of medium-hard materials such as rice, wood, leather or Plastics and for sample preparation according to RoHS – such as for verification of hexavalent chromium.

Sieve rings determine the end fineness of the sample.

Sieve rings TiN-coated are offered with trapezoidal perforation. The trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings TiN-coated with 0.12 mm, 0.5 mm and 1 mm trapezoidal perforations and impact rotors with 12 and 24 ribs, TiN-coated can be ordered.

Please note: for heavy-metal-iron-free grinding and sample preparation according to RoHS, a PTFE-coated lid and collecting vessel are always required, order no. 14.3750.00.

| General specifications | |

| Material | Titanium nitride – TiN |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Titanium nitride TiN | 100 |

For heavy-metal and iron-free grinding of medium-hard materials such as rice, wood, leather or Plastics and for sample preparation according to RoHS – such as for verification of hexavalent chromium.

Sieve rings determine the end fineness of the sample.

Sieve rings TiN-coated are offered with trapezoidal perforation.

The trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings TiN-coated with 0.12 mm, 0.2 mm and 1 mm trapezoidal perforations and impact rotors with 12 and 24 ribs, TiN-coated can be ordered.

Please note: for heavy-metal-iron-free grinding and sample preparation according to RoHS, a PTFE-coated lid and collecting vessel are always required, order no. 14.3750.00.

| General specifications | |

| Material | Titanium nitride – TiN |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Titanium nitride TiN | 100 |

For heavy-metal and iron-free grinding of medium-hard materials such as rice, wood, leather or plastics.

Sieve rings determine the end fineness of the sample and for sample preparation according to RoHS – such as for verification of hexavalent chromium.

Sieve rings TiN-coated are offered with trapezoidal perforation. The trapezoidal perforations improve size reduction through extra shearing action.

Additionally, sieve rings TiN-coated with 0.12 mm, 0.2 mm and 0.5 mm trapezoidal perforations and impact rotors with 12 and 24 ribs, TiN-coated can be ordered.

Please note: for heavy-metal-iron-free grinding and sample preparation according to RoHS, a PTFE-coated lid and collecting vessel are always required, order no. 14.3750.00.

| General specifications | |

| Material | Titanium nitride – TiN |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Titanium nitride TiN | 100 |

ACCESSOIRES DE BROYAGE POUR ÉCHANTILLONS DIFFICILES À BROYER ET SENSIBLES À LA TEMPÉRATURE

Combinée avec un tamis annulaire, la bague à percussion FRITSCH produit une fragmentation douce de l'échantillon. Les batteurs de la bague à percussion font office de stators et assurent une fragmentation supplémentaire du matériau. Idéal pour les matériaux particulièrement sensibles à la chaleur, à l'instar des peintures en poudre ou des matières plastiques, et pour réaliser sans problème le pré-broyage et le broyage fin d'échantillons durs-cassants à mous, gras ou chargés d'humidité résiduelle. Le rotor correspondant et le tamis annulaire de la bague à percussion doivent être commandés à part.

BAGUE À PERCUSSION POUR LE BROYAGE D'ÉCHANTILLONS DIFFICILES À BROYER ET SENSIBLES À LA TEMPÉRATURE

For difficult-to-mill samples, temperature-sensitive samples and plastics

The impact bar enables together with a sieve ring a very gentle comminution of the sample. The bar acts as a stator on which the material is additionally beaten. The result: increased grinding performance for a particularly fast and effective grinding that minimises the thermal load. Ideal for especially heat-sensitive materials such as powder coatings or plastics as well as for smooth pre-crushing and fine comminution of hard-brittle to soft, fatty or samples with residual moisture.

(Please note: impact rotor and special sieve ring are additionally necessary!)

| General specifications | |

| Material | Stainless steel – 1.4057 |

| ISO/EN/DIN code | X17CrNi16-2 |

| AISI code | 431 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 77.7–80.8 |

| Carbon – C | 0.12–0.22 |

| Silicon – Si | ≤ 1.0 |

| Manganese – Mn | ≤ 1.5 |

| Chromium – Cr | 15–17 |

| Nickel – Ni | 1.5–2.5 |

| Phosphorus – P | ≤ 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7g/cm³ |

| Hardness | 295 HB |

Explanations on hardness data

TAMIS ANNULAIRES EN ACIER INOXYDABLE POUR BAGUE À PERCUSSION 316L

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

Sieve rings with round perforations achieve medium fineness with small grain bands.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with round perforations achieve medium fineness with small grain bands.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with round perforations achieve medium fineness with small grain bands.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with round perforations achieve medium fineness with small grain bands.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

- special sieve ring and only for the use together with the impact bar -

Sieve rings determine the end fineness of the sample.

Sieve rings with trapezoidal perforations and round perforations are available.

Sieve rings with round perforations achieve medium fineness with small grain bands.

Sieve rings with trapezoidal perforations improve size reduction through extra shearing action.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

ACCESSOIRES DE BROYAGE SANS TAMIS

Le broyage sans tamis de matériaux les plus difficiles, mi-durs, huileux ou graisseux. comme les cires et les paraffines, exige un rotor à pointes et le couvercle de chambre de broyage correspondant, à insert pour pointes.

INSERT DE POINTES POUR BROYAGE SANS TAMIS

consisting of pin rotor and grinding chamber lid with pin insert.

For grinding without a sieve for the most difficult, medium-hard, oil or grease containing materials such as waxes or paraffins.

To discharge and collect large quantities which need to be ground use the conversion kit for grinding large quantities.

ACCESSOIRES DE FRAGMENTATION DE GRANDES QUANTITÉS

Un kit de transformation spécial permet de broyer des quantités importantes, que la configuration spécifique présente un rotor, des tamis annulaires, une bague à percussions ou un insert de pointes. Vous pouvez ainsi broyer des échantillons de volume pouvant atteindre 1 l en une seule opération, sans qu'il soit nécessaire d'ouvrir la chambre de broyage ou de vider le bac collecteur.

ACCESSOIRES DE FRAGMENTATION DE GRANDES QUANTITÉS

consisting of pan with outlet and flange-mount nylon support sack (outside) for the paper filter bag (inside).

Regardless of the specific configuration of rotor, sieve rings, impact bar or pin insert, the PULVERISETTE 14 is capable of grinding of large quantities with the special conversion kit: Consisting of a special collecting vessel with outlet and flange-mount nylon support sack for easily replaceable paper filter bags. This allows the comminution of sample quantities of up to 1 litre in a single step without the need to open the grinding chamber and empty the collecting pan during the process.

Our suggestion: During grinding of very light materials, the material yield can be significantly improved by the high air circulation of the conversion kit for grinding large quantities – even when grinding smaller quantities!

Another suggestion: During grinding of temperature-sensitive samples, the conversion kit for grinding large quantities with its large nylon support sack ensures a high air throughput, resulting in even better cooling.

Set of paper filter bags for conversion kit for grinding large quantities

Set = 20 pieces paper filter bags

ACCESSOIRES D'ASPIRATION D'ÉCHANTILLON AVEC CYCLONES

La combinaison du broyeur rapide à rotor FRITSCH PULVERISETTE 14 classic line et du cyclones FRITSCH est idéale pour le broyage fin de matériaux sensibles à la température, à l'instar des peintures en poudre ou des matières plastiques, ou du pré-broyage et du broyage fin d'échantillons durs-cassants à mous, gras ou chargés d'humidité résiduelle.

Nous offrons deux modèles: Cyclone haute performance et Cyclone pour petite quantités.

CHOISISSEZ Cyclone haute performance ET LES ACCESSOIRES

The compact FRITSCH high-performance Cyclone separator, which is made completely out of stainless steel 304, is particularly indispensable in the analytical sector and the food and pharmaceutical industries. Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids, but particularly to media containing chlorides – and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. The Cyclone separator can also be fully dismantled, meaning that it can be completely emptied, flooded and sterilised.

Your advantage: reliable protection against cross-contamination.

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

Sample glass 1 litre for sample exhaustion with the high-performance Cyclone separator.

The sample glass with 2 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The sample glass with 5 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

Cyclone de petites quantités et Accessoires

Small volume Cyclone separator made of plastic for sample exhaustion of small sample quantities, incl. 250 ml sample glass.

We designed the compact FRITSCH small volume Cyclone separator especially for exhaustion of small sample quantities. It is made of plastic, can be dismantled completely and cleaned in a dishwasher for reliably preventing contaminations.

The comminuted sample is collected in a 250 ml sample glass, in which it can also be transported and stored. Alternatively a sample glass 500 ml can also be screwed-on and ordered: order no. 27.1460.00.

The small volume Cyclone separator can be combined with the exhaust system order no. 43.9070.00 or can also be used with the supplied fine-dust filter 80-100 µm for passive utilisation. Replacement fine-dust-filters 80-100 µm can be reordered: order no. 45.8218.16.

Replacement fine-dust filter 80-100 µm for small volume Cyclone separator for passive utilisation.

Replacement fine-dust filter 35 – 40 μm for small volume Cyclone separator for passive utilisation.

Sample bottle with screw lid, thread of sample bottle GL55.

Sample bottle can be used with dividing heads, division ratio 1:8.

Furthermore a sample vessel 32 ml with lid, article-number 83.3190.16, is available, which can be inserted in the sample bottles 250 ml and 500 ml for dividing smallest sample quantities.

Sample glass can also be used for sample exhaustion with the small volume Cyclone separator.

Sample bottle with screw lid, thread of sample bottle GL55, sample bottle can be used with dividing heads, division ratio 1:8 and 1:10.

Furthermore a sample vessel 32 ml with lid, article-number 83.3190.16, is available, which can be inserted in the sample bottles 250 ml and 500 ml for dividing smallest sample quantities.

The sample glass is recommended for sample exhaustion with the small volume Cyclone separator for sample discharges smaller than 500 ml, since only a 500 ml sample glass is included in the delivery of the small volume performance Cyclone separator.

Système d’aspiration pour cyclone de haute performance et de petites quantités

The exhaust system, dust category "M" according to DIN EN 60335-2-69 for 230 V/1~, 50/60 Hz, 1600 Watt is versatile:

For combination with the high performance and small volume cyclones.

To operate the FRITSCH Cyclones you need an exhaust system. The strong airflow ensures simple feeding, increases throughput, and reduces the thermal load of the samples. The high performance and small volume Cyclone separator can be combined with Universal Cutting Mills PULVERISETTE 19, the Variable Speed Rotor Mill PULVERISETTE 14 premium line and classic line. The small volume cyclone can also be combined with the Variable Speed Rotor Mill PULVERISETE 14 premium line and classic line even for passive utilisation – without sample exhaust.

The high-performance cyclone is ideal for combination with the Universal Cutting Mills PULVERISETTE 19 large, the Cross Beater Mill PULVERISETTE 16 and the Disk Mill PULVERISETTE 13 premium line for optimal sample extraction and for comminution of larger quantities.

For cooling of the Variable Speed Rotor Mill PULVERISETTE 14 premium line

By connecting the exhaust system with the connecting piece order no. 14.4214.00, the cooling of the mill can easily be enhanced.

For connecting to Disk Mill PULVERISETTE 13 premium line

The exhaust is simply connected to the PULVERISETTE 13 premium line and operated via a start and stop button on the instrument – for dust free comminution.

For connecting to the Jaw Crusher PULVERISETTE 1, Modell I + II classic line

Simply connect the exhaust system to the integrated connection of the PULVERISETTE 1. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For connecting to the Disk Mill PULVERISETTE 13 classic line

The exhaust system can be easily connected to the PULVERISETTE 13 classic line. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

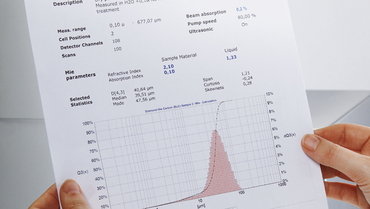

For exhaustion of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT

An exhaust system is necessary to ensure automatic sample exhaustion during dry measurement. When the measurement is completed it can also be easily used to manually clean the feeder.

Please note that the exhaust system article no. 43.9070.00, is not equipped with a fine filter and therefore dust may escape. Please consider the valid occupational health and safety regulations. This exhaust system is mostly recommended for dust-free grinding and the vacuuming of during the process developing fine dust in the upper part of the grinding chamber and for the cleaning of the grinding parts.

For vacuuming of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT, we recommended we recommend the exhaust system article no. 43.9060.00, which is equipped with a hose and an ultra-fine filter of dust class "H" according to DIN EN 60335-2-69, so that the escape of fine dust is reduced.

1 pack = 5 pieces

One pack is included in the scope of delivery of the exhaust system (article No. 43.9070.00).

These fleece filter bags should be used for the vacuuming off of fine, dry materials.

For the vacuuming off of coarse, wet materials are plastic bags available (article no. 43.9052.00).

1 pack = 5 pieces

One pack is included in the order of the exhaust system (article No. 43.9070.00).

These plastic bags should be used for the vacuuming off of coarse, wet materials.

For the vacuuming off of fine, dry materials are paper filter bags available (article no. 43.9055.00).

CERTIFICATION

Formulaire à remplir par l'utilisateur, aide à la qualification d'appareils dans le système de gestion de qualité, pour le broyeur rapide à rotor PULVERISETTE 14 classic line.

Certification

IQ/OQ documentation (questionnaire format - implementation not included)

for the independent utilization for the support of instrument qualification in the quality management system for the Variable-Speed Rotor Mill Rotor PULVERISETTE 14 classic line.

ACCESSOIRES D'ALIMENTATION AUTOMATIQUE

Afin que l'alimentation en échantillon soit continue pendant tout le broyage, même en présence des plus petites quantités de matériau, PULVERISETTE 14 classic line peut être combinée avec la trémie d'alimentation à vibrations FRITSCH LABORETTE 24. Le micro-broyeur adapte automatiquement l'arrivée d'échantillon à son état de contrainte du moment, par l'intermédiaire d'une liaison directe.

ACCESSOIRES D'ALIMENTATION AUTOMATIQUE

Vibratory Feeder LABORETTE 24 with V-shaped channel, funnel and control unit for 200-240 V/1~, 50-60 Hz, 25 Watt.

Details Vibratory Feeder LABORETTE 24

Vibratory Feeder LABORETTE 24 with V-shaped channel, funnel and control unit for 100-120 V/1~, 50-60 Hz, 25 Watt.

Details Vibratory Feeder LABORETTE 24

solid stand - height adjustable, rotatable, stable

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Vibratory Feeder LABORETTE 24.