Divers Broyeurs à disques

AUTRES GROUPES DE PRODUITS

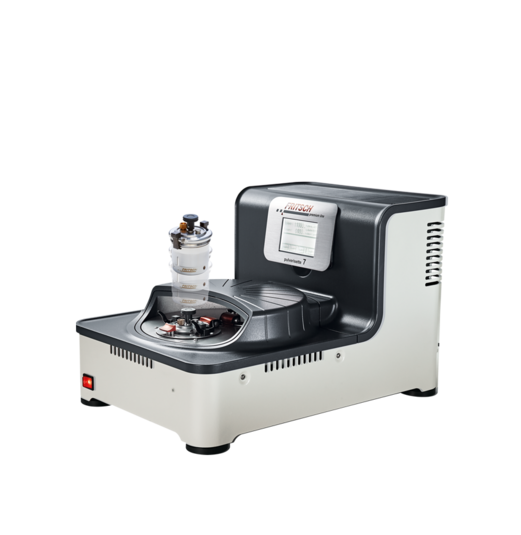

Broyeur à disques

PULVERISETTE 13

premium lineVeuillez tenir compte des points suivants : Chaque broyeur à disques FRITSCH PULVERISETTE 13 premium line doit être équipé au moins d'un disque de broyage fixe et d'un disque de broyage mobile. Ils sont disponibles en 4 matériaux différents. En règle générale, les disques de broyage choisis sont du même matériau, dont la dureté doit toujours être supérieure à celle de l'échantillon à broyer.

Le broyeur à disques PULVERISETTE 13 premium line est également disponible avec un revêtement intérieur intégral de la chambre de broyage en polymère, lorsque le broyage doit avoir lieu sans métaux.

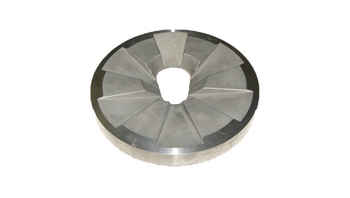

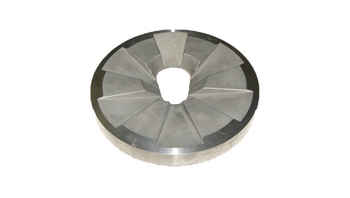

Disques de broyage

-

Données matériau des disques de broyage fixe et mobile

Matériau Composant principal du matériau Densité en g/cm³

écartementRésistance à l'abrasion Type d'échantillon acier moulé trempé Fe – Cr 3,85 bonne échantillons durs, cassants acier au manganèse Fe - Mn 7,9-8 bonne échantillons très durs, cassants métal dur carbure de tungstène WC 14,05 très bonne échantillons très durs, abrasifs oxyde de zirconium ZrO2 5,7 bonne échantillons mi-durs, cassants broyage sans métaux

Veuillez choisir au moins un disque de broyage fixe et un disque de broyage mobile. Ils sont disponibles en 4 matériaux différents. Les disques de broyage en oxyde de zirconium sont adaptés uniquement au broyage des matériaux céramiques, minéraux et équivalents, mais en aucun cas à celui des échantillons durs et tenaces, en métal par exemple.

Disques de broyage

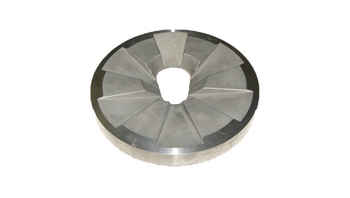

for the comminution of hard, brittle samples

General material specification:

Material: hardened steel cast - 1.2602

Abrasion resistance: good

Suitable for: hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Cast steel, hardened – 1.2602 |

| ISO/EN/DIN code | GX165CrMoV12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 85.94 - 83.59 |

| Carbon – C | 1.55 – 1.75 |

| Silicon – Si | 0.25 – 0.4 |

| Manganese – Mn | 0.2 – 0.4 |

| Phosphorus – P | 0.03 |

| Sulphur – S | 0.03 |

| Chromium – Cr | 11 - 12 |

| Molybdenum – Mo | 0.5 – 0.7 |

| Vanadium – V | 0.1 – 0.5 |

| W | 0.4 -0.6 |

| Physical and mechanical properties | |

| Density | 3.85 g/cm³ |

| Hardness | 60 HRC |

Explanations on hardness data

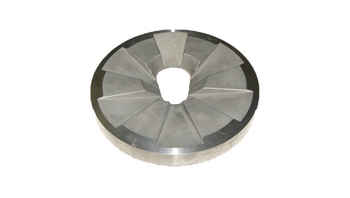

for the comminution of hard, brittle samples

General material specification:

Material: hardened steel cast - 1.2602

Abrasion resistance: good

Suitable for: hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Cast steel, hardened – 1.2602 |

| ISO/EN/DIN code | GX165CrMoV12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 85.94 - 83.59 |

| Carbon – C | 1.55 – 1.75 |

| Silicon – Si | 0.25 – 0.4 |

| Manganese – Mn | 0.2 – 0.4 |

| Phosphorus – P | 0.03 |

| Sulphur – S | 0.03 |

| Chromium – Cr | 11 - 12 |

| Molybdenum – Mo | 0.5 – 0.7 |

| Vanadium – V | 0.1 – 0.5 |

| W | 0.4 -0.6 |

| Physical and mechanical properties | |

| Density | 3.85 g/cm³ |

| Hardness | 60 HRC |

Explanations on hardness data

for the comminution of very hard, brittle samples

General material specification:

Material: manganese steel - 1.3401

Abrasion resistance: good

Suitable for: very hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Manganese steel – 1.3401 |

| ISO/EN/DIN code | X120Mn12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 83.56 -85.96 |

| Chromium – Cr | < 1,50 |

| Silicon – Si | 0,3–0,5 |

| Manganese – Mn | 12,0–13.0 |

| Carbon – C | 1.1 -1.3 |

| Phosphorus – P | < 0.1 |

| Sulphur – S | < 0.04 |

| Physical and mechanical properties | |

| Density | 7.9–8 g/cm³ |

| Hardness | 27–32 HRC |

Explanations on hardness data

for the comminution of very hard, brittle samples

General material specification:

Material: manganese steel - 1.3401

Abrasion resistance: good

Suitable for: very hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Manganese steel – 1.3401 |

| ISO/EN/DIN code | X120Mn12 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 83.56 -85.96 |

| Chromium – Cr | < 1,50 |

| Silicon – Si | 0,3–0,5 |

| Manganese – Mn | 12,0–13.0 |

| Carbon – C | 1.1 -1.3 |

| Phosphorus – P | < 0.1 |

| Sulphur – S | < 0.04 |

| Physical and mechanical properties | |

| Density | 7.9–8 g/cm³ |

| Hardness | 27–32 HRC |

Explanations on hardness data

for the comminution of very hard, abrasive samples

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: very hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 85.00 |

| Cobalt – Co | 15.00 |

| Physical and mechanical properties | |

| Density | 14.05 g/cm³ |

| Hardness | 1020 HV10 |

Explanations on hardness data

for the comminution of very hard, abrasive samples

General material specification:

Material: hardmetal tungsten carbide - WC

Abrasion resistance: very good

Suitable for: very hard, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Tungsten carbide - WC |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – TC | 85.00 |

| Cobalt – Co | 15.00 |

| Physical and mechanical properties | |

| Density | 14.05 g/cm³ |

| Hardness | 1020 HV10 |

Explanations on hardness data

for the comminution of medium-hard, brittle samples and metal-free grinding

General material specification:

Material: zirconium oxide ZrO2

Abrasion resistance: good

Suitable for: medium-hard, brittle samples, metal-free grinding

Detailed information about the material you will find in the element analysis.

Grinding disks of zirconium oxide are only suitable for grinding ceramic materials, minerals etc. and never for hard-tough samples, such as metals.

| General specifications | |

| Material | Zirconium oxide – ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.5 |

| Yttrium oxide – Y2O3 | 5.1 |

| SiO2, CaO, MgO, Al2O3 | < 0.4 |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness | 12.5 x 10³ Nmm-² HV |

Explanations on hardness data

for the comminution of medium-hard, brittle samples and metal-free grinding

General material specification:

Material: zirconium oxide ZrO2

Abrasion resistance: good

Suitable for: medium-hard, brittle samples, for metal-free grinding

Detailed information about the material you will find in the element analysis.

Grinding disks of zirconium oxide are only suitable for grinding ceramic materials, minerals etc and never for hard-tough samples, such as metals.

| General specifications | |

| Material | Zirconium oxide – ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.5 |

| Yttrium oxide – Y2O3 | 5.1 |

| SiO2, CaO, MgO, Al2O3 | < 0.4 |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness | 12.5 x 10³ Nmm-² HV |

Explanations on hardness data

Accessoires de broyage sans métaux

Idéal pour les techniques médicales et dentaires : Nous équipons en option votre broyeur PULVERISETTE 13 premium line d'un revêtement interne intégral en polymère, ainsi que de disques de broyage en oxyde de zirconium : garantie absolue pour un broyage de l'échantillon sans aucun contact métallique.

ACCESSOIRES DE BROYAGE SANS métaux

Ideal for medical and dental engineering: On request, we can equip your PULVERISETTE 13 premium line with a complete polymer interior coating together with grinding disks made of zirconium oxide – the perfect prerequisite for grinding without any contact of the sample with metal.

Please note: fixed and movable grinding disks made of zirconium oxide are additionally necessary:

fixed grinding disk, 200 mm diameter, zirconium oxide*: order no. 13.2100.27

movable grinding disk, 200 mm diameter, zirconium oxide*: order no. 13.2110.27

*Grinding parts made of zirconium oxide are only suitable for grinding ceramic materials, minerals, etc. and never for hard-tough samples, such as metals.

Epuisement des échantillons avec le séparateur Cyclone et pour le broyage de grandes quantités

La combinaison du broyeur à disques PULVERISETTE 13 premium line avec le cyclone haute performance permet un nettoyage et un remplissage plus faciles, l'utilisation de cassettes de tamisage plus fines pour des finesses finales plus élevées, accélère le débit, et maintient la charge thermique des échantillons à un faible niveau - et ce même pour des matériaux qui sont autrement difficiles à broyer finement.

Séparateur cyclone haute performance

The FRITSCH high-performance Cyclone separator completely made of stainless steel 316L is particularly indispensable in the analytical sector and in the food and pharmaceutical industries, and for the processing of heterogeneous mixtures of material, e.g. in the cement industry.

Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. The comminuted sample is drawn into a screwed-on collecting vessel or in a smaller sample glass, in which it can also be transported and stored. In addition, it can be completely dismantled, fully emptied, flooded and sterilised, and thus offers reliable protection against cross-contamination.

The advantages of the high-performance Cyclone separator at a glance

- Faster throughput

- Improved discharge of material from the grinding chamber

- Additional strong cooling of the grinding material and grinding parts

- Efficient size reduction of temperature-sensitive samples, electrostatically-charged plastics or powder coatings

- Ideal for light materials, small sample quantities and finer sieve sizes

- Highly efficient continuous comminution of large quantities

RÉCIPIENTS COLLECTEUR POUR CYCLONES HAUTE PERFORMANCE

Sample glass 1 litre for sample exhaustion with the high-performance Cyclone separator.

The sample glass with 2 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The sample glass with 5 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The collecting vessel 20 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The collecting vessel 60 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

SYSTÈME D'ASPIRATION ET ACCESSOIRES POUR CYCLONES HAUTE PERFORMANCE et pour un meulage sans poussière

The exhaust system, dust category "M" according to DIN EN 60335-2-69 for 230 V/1~, 50/60 Hz, 1600 Watt is versatile:

For combination with the high performance and small volume cyclones.

To operate the FRITSCH Cyclones you need an exhaust system. The strong airflow ensures simple feeding, increases throughput, and reduces the thermal load of the samples. The high performance and small volume Cyclone separator can be combined with Universal Cutting Mills PULVERISETTE 19, the Variable Speed Rotor Mill PULVERISETTE 14 premium line and classic line. The small volume cyclone can also be combined with the Variable Speed Rotor Mill PULVERISETE 14 premium line and classic line even for passive utilisation – without sample exhaust.

The high-performance cyclone is ideal for combination with the Universal Cutting Mills PULVERISETTE 19 large, the Cross Beater Mill PULVERISETTE 16 and the Disk Mill PULVERISETTE 13 premium line for optimal sample extraction and for comminution of larger quantities.

For cooling of the Variable Speed Rotor Mill PULVERISETTE 14 premium line

By connecting the exhaust system with the connecting piece order no. 14.8128.00, the cooling of the mill can easily be enhanced.

For connecting to Disk Mill PULVERISETTE 13 premium line

The exhaust is simply connected to the PULVERISETTE 13 premium line and operated via a start and stop button on the instrument – for dust free comminution.

For connecting to the Jaw Crusher PULVERISETTE 1, Modell I + II classic line

Simply connect the exhaust system to the integrated connection of the PULVERISETTE 1. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For connecting to the Disk Mill PULVERISETTE 13 classic line

The exhaust system can be easily connected to the PULVERISETTE 13 classic line. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For exhaustion of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT

An exhaust system is necessary to ensure automatic sample exhaustion during dry measurement. When the measurement is completed it can also be easily used to manually clean the feeder.

Please note that the exhaust system article no. 43.9070.00, is not equipped with a fine filter and therefore dust may escape. Please consider the valid occupational health and safety regulations. This exhaust system is mostly recommended for dust-free grinding and the vacuuming of during the process developing fine dust in the upper part of the grinding chamber and for the cleaning of the grinding parts.

For vacuuming of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT, we recommended we recommend the exhaust system article no. 43.9060.00, which is equipped with a hose and an ultra-fine filter of dust class "H" according to DIN EN 60335-2-69, so that the escape of fine dust is reduced.

1 pack = 5 pieces

One pack is included in the scope of delivery of the exhaust system (article No. 43.9070.00).

These fleece filter bags should be used for the vacuuming off of fine, dry materials.

For the vacuuming off of coarse, wet materials are plastic bags available (article no. 43.9052.00).

1 pack = 5 pieces

One pack is included in the order of the exhaust system (article No. 43.9070.00).

These plastic bags should be used for the vacuuming off of coarse, wet materials.

For the vacuuming off of fine, dry materials are paper filter bags available (article no. 43.9055.00).

Certification

Documentation IQ/OQ à remplir par l'utilisateur, aide à la qualification d'appareils dans le système de gestion de qualité, pour le broyeur à disques PULVERISETTE 13 premium line.

Certification

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Disk Mill PULVERISETTE 13 premium line.