Puissance et robustesse

Les concasseurs à mâchoires sont idéaux pour réaliser le pré-broyage de matériaux très durs, durs, mi-durs, cassants, résistants et sensibles à la température. L'échantillon est fragmenté sous l'effet la pression élevée qui existe entre deux plaques de broyage, l'une fixe et l'autre mobile.

Afin d'éviter toute abrasion perturbatrice, les accessoires de broyage sont proposés en différents types d'acier, en carbure de tungstène et en oxyde de zirconium.

-

Concasseurs à mâchoires polyvalents classic line

Le concasseur compact

- Fragmentation rapide et uniforme

- Granulométrie finale 1–15 mm

- Nettoyage facile

- Retrait simple de la mâchoire de concassage

- Largeur de l'écartement réglable en 10 étapes entre les mâchoires de concassage

- Fonctionnement sûr et sans poussière

- Cinématique de mâchoires de broyage variable pour une granulométrie finale supérieure

- Accès particulièrement facile à la trémie, remplissage et nettoyage faciles et rapides

RECHERCHE DE PRODUIT

2 Résultats

Details

PULVERISETTE 1

classic line

- Taille initiale max. (selon nature de l’échantillon)

- 60 mm

- Débit max. en continu

- 140 kg/h

- Granulométrie finale (selon l’ouverture)

- 1 - 15 mm

- Puissance absorbée

- 1.7 kW

Details

PULVERISETTE 1

classic line

- Taille initiale max. (selon nature de l’échantillon)

- 95 mm

- Débit max. en continu

- 200 kg/h

- Granulométrie finale (selon l’ouverture)

- 1 - 15 mm

- Puissance absorbée

- 2.6 kW

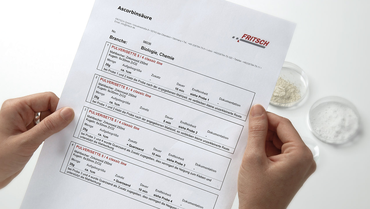

Téléchargements

Prospectus sur les Broyeurs à mâchoires et à disques classic line

pour Concasseur à mâchoires PULVERISETTE 1 classic line, Broyeur à disques PULVERISETTE 13 classic line, Broyeur à disques oscillants PULVERISETTE 9 et Press à pastiller