A group of students of the Geschwister-Scholl vocational school Saarburg-Hermeskeil and French exchange students visited Idar-Oberstein.

During their visit to Idar-Oberstein the vocational students – including 8 French students, experienced how in the gemstone metropolis, traditions in the field of gemstone processing merge into innovations: first they visited the industrial monument Bengel and afterwards FRITSCH Milling and Sizing.

Because the beginnings of FRITSCH can also be found in the tradition of gemstone processing: 1920 the company was founded as a technical precious stones dealer and sold agate mortars for production of powders to pharmacists and chemical laboratories. But already in the mid-fifties FRITSCH specialized in the production of high-tech laboratory instruments. Agate is still used today for the production of grinding balls and grinding bowls.

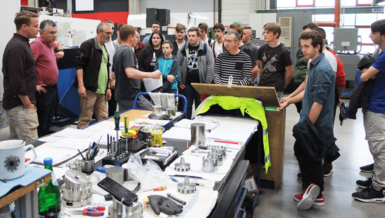

During ongoing operation, the group of students and their teachers gained an insight into the diverse and highly technical production processes of the company FRITSCH Milling and Sizing. They were able to convince themselves of the processing and gained an insight in how extensive the work and logistic processes are until laboratory instruments are delivered.